b

Smallest

XOmetry

Largest

Enclosure Draft

Design Criteria

Multiturn Pot outside case.

for Buck type.

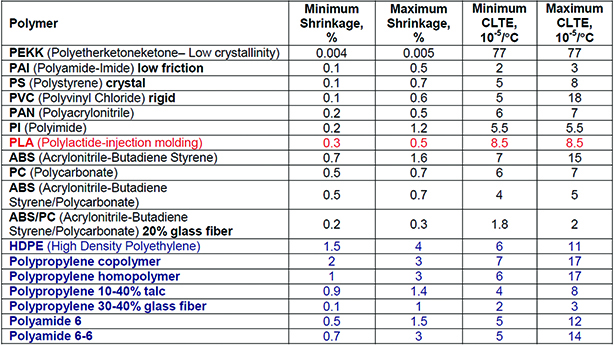

3D Filament database shrinkage factors.

Deresin Sintering

Test Equipment

Power Supplies

End plantes

IEC one

IEC 330

Banana Jacks

Banana Binding Posts

Volt Meters

Current Meter

- Dimensions:48mm*29mm*26mm

- Mounting Hole: about 46 * 27 mm / 1.81 * 1.07 inches

Aircraft

Lighter Than Alu Stronger than Steel and able to stand exhaust temperatures.

Car Body Parts

Unobtanium problem solvers.

Knobs for Electronics

Plated Plastic Service

Etched Metals

Embedded parts and materials.

Embed IEC connector in Panel

Print panel On 45

Examples of Benchies Bridging Results.

Circuits

BIcycle Parts

Medical Items

Jigs

Test Fixtures

Shortcomming of Kobra... Not M command for interupt at height.

Can be overcame by octoprint.

I have this issue as well. I power cycle the machine, then use the "Axis" menu to raise

it a good 4-6 inches above the print. Then I "Home" it from the LCD menu.

Then resume, it seems to go back to printing without issue after that.

or if the filament is broken. Easily continue printing from power failure or pause, saves time and filament.

https://www.youtube.com/watch?v=woGJCofyIsQ

Gcode Pause

auto dump

https://www.youtube.com/watch?v=MMSnJPhPFko

Tas incetives

Additive mfg home mfg revolution

Makerforge

Mic Proximity sensor gain dip

Basf

2 Printers

Gold Filament

4 Printer configuration

Additive Manufactured

Local uses

Systematically around property life office

Mailbox NUmbers AHouse Numbers

House Numbers

QR Code Medalion

Print Backing plate then qr code

Paypal ID

Local Filament Manufacture

Streamlined Communications

Mailbox sensor

Solar Powered Mailbox

3d printed battery

Glow in dark.

Kobra Issue

No stop at level.

Ideal printer .

Stop at level.

Dual Head

All metal

Direct Extruder

Calibration Settings for Filaments

Dimensional Calibration Tool

ABS Table

Clearances:

.25 mm for pcb drop in.

Simplify 3d Filament table.

| Name of the polymer | Explicit name of the polymer | Min Value(%) | Max Value(%) |

|---|---|---|---|

| ABS | Acrylonitrile-Butadiene Styrene | 0.700 | 1.600 |

| ABS FR | Acrylonitrile-Butadiene Styrene flame retardant | 0.300 | 0.800 |

| ABS High Heat | Acrylonitrile-Butadiene Styrene High Heat | 0.400 | 0.900 |

| ABS High Impact | Acrylonitrile-Butadiene Styrene High Impact | 0.400 | 0.900 |

| ABS/PC | Acrylonitrile-Butadiene Styrene/Polycarbonate | 0.500 | 0.700 |

| ABS/PC 20% GF | Acrylonitrile-Butadiene Styrene/Polycarbonate 20% glass fiber | 0.200 | 0.300 |

| ABS/PC FR | Acrylonitrile-Butadiene Styrene/Polycarbonate flame retardant | 0.300 | 0.600 |

| Amorphous TPI Blend, Ultra-high heat, Chemical Resistant (High Flow) | Amorphous TPI Blend, Ultra-high heat, Chemical Resistant (High Flow) | 0.800 | 1.000 |

| Amorphous TPI Blend, Ultra-high heat, Chemical Resistant (Standard Flow) | Amorphous TPI Blend, Ultra-high heat, Chemical Resistant (Standard Flow) | 0.800 | 1.000 |

| Amorphous TPI, High Heat, High Flow, Transparent, Lead-Free Solderable (High Flow) | Amorphous TPI, High Heat, High Flow, Transparent, Lead-Free Solderable (High Flow) | 1.000 | 1.200 |

| Amorphous TPI, High Heat, High Flow, Transparent, Lead-Free Solderable (Standard Flow) | Amorphous TPI, High Heat, High Flow, Transparent, Lead-Free Solderable (Standard Flow) | 1.000 | 1.200 |

| Amorphous TPI, Moderate Heat, Transparent | Amorphous TPI, Moderate Heat, Transparent | 0.500 | 0.700 |

| Amorphous TPI, Moderate Heat, Transparent (Food Contact Approved) | Amorphous TPI, Moderate Heat, Transparent (Food Contact Approved) | 0.500 | 0.700 |

| Amorphous TPI, Moderate Heat, Transparent (Mold Release grade) | Amorphous TPI, Moderate Heat, Transparent (Mold Release grade) | 0.500 | 0.700 |

| Amorphous TPI, Moderate Heat, Transparent (Powder form) | Amorphous TPI, Moderate Heat, Transparent (Powder form) | 0.500 | 0.700 |

| ASA | Acrylonitrile Styrene Acrylate | 0.400 | 0.700 |

| ASA/PC | Acrylonitrile Styrene Acrylate/Polycarbonate | 0.300 | 0.700 |

| ASA/PC FR | Acrylonitrile Styrene Acrylate/Polycarbonate flame retardant | 0.400 | 0.800 |

| ASA/PVC | Acrylonitrile Styrene Acrylate/Polyvinyl Chloride | 0.300 | 0.700 |

| CA – Cellulose Acetate | Cellulose Acetate | 0.300 | 1.000 |

| CAB – Cellulose Acetate Butyrate | Cellulose Acetate Butyrate | 0.200 | 0.900 |

| Celllulose Diacetate- Pearlescent Films | Celllulose Diacetate- Pearlescent Films | 1.000 | 1.500 |

| Celllulose Diacetate-Matt Film | Celllulose Diacetate-Matt Film | 1.000 | 1.500 |

| CP – Cellulose Proprionate | Cellulose Proprionate | 0.100 | 0.900 |

| CPVC – Chlorinated Polyvinyl Chloride | CPVC – Chlorinated Polyvinyl Chloride | 0.300 | 0.700 |

| ETFE | Ethylene Tetrafluoroethylene | 3.000 | 4.000 |

| EVA | Ethylene Vinyl Acetate | 0.400 | 3.500 |

| FEP | Fluorinated Ethylene Propylene | 3.000 | 6.000 |

| HDPE – High Density Polyethylene | HDPE – High Density Polyethylene | 1.500 | 4.000 |

| HIPS – High Impact Polystyrene | HIPS – High Impact Polystyrene | 0.200 | 0.800 |

| HIPS FR V0 | High Impact Polystyrene flame retardant V0 | 0.300 | 0.600 |

| LCP | Liquid Crystal Polymer | 0.100 | 0.600 |

| LCP CF | Liquid Crystal Polymer carbon fiber | 0.100 | 0.500 |

| LCP GF | Liquid Crystal Polymer glass fiber | 0.100 | 0.400 |

| LCP MINERAL | Liquid Crystal Polymer mineral | 0.100 | 0.500 |

| LDPE – Low Density Polyethylene | LDPE – Low Density Polyethylene | 2.000 | 4.000 |

| LLDPE – Linear Low Density Polyethylene | LLDPE – Linear Low Density Polyethylene | 2.000 | 2.500 |

| MABS | Transparent Acrylonitrile Butadiene Styrene | 0.400 | 0.700 |

| PA 11 30% Glass fiber reinforced | Polyamide 11 30% Glass fiber reinforced | 0.500 | 0.500 |

| PA 11 conductive | Polyamide 11 conductive | 0.700 | 2.000 |

| PA 11 flexible | Polyamide 11 flexible | 1.400 | 1.800 |

| PA 11 rigid | Polyamide 11 rigid | 0.700 | 2.000 |

| PA 12 conductive | Polyamide 12 conductive | 0.700 | 2.000 |

| PA 12 fiber reinforced | Polyamide 12 fiber reinforced | 0.700 | 2.000 |

| PA 12 flexible | Polyamide 12 flexible | 0.700 | 2.000 |

| PA 12 glass filled | Polyamide 12 glass filled | 0.700 | 2.000 |

| PA 12 rigid | Polyamide 12 rigid | 0.700 | 2.000 |

| PA 46 | Polyamide 46 | 1.500 | 2.000 |

| PA 46 30% GF | Polyamide 46 30% glass fiber | 0.300 | 1.300 |

| PA 6 | Polyamide 6 | 0.500 | 1.500 |

| PA 6-10 | Polyamide 6-10 | 1.000 | 1.300 |

| PA 66 | Polyamide 6-6 | 0.700 | 3.000 |

| PA 66 30% GF | Polyamide 6-6 30% glass fiber | 0.500 | 0.500 |

| PA 66 30% mineral filled | Polyamide 6-6 30% mineral filled | 0.600 | 1.000 |

| PA 66 IM 15-30% GF | Polyamide 6-6 impact modified 15-30% glass fiber | 0.200 | 0.600 |

| PA 66 impact modified | Polyamide 6-6 impact modified | 1.200 | 3.000 |

| PAI | Polyamide-Imide | 0.600 | 1.000 |

| PAI 30% GF | Polyamide-Imide 30% glass fiber | 0.100 | 0.300 |

| PAI low friction | Polyamide-Imide low friction | 0.100 | 0.500 |

| PAN | Polyacrylonitrile | 0.200 | 0.500 |

| PAR | Polyarylate | 0.900 | 1.200 |

| PARA 30-60% GF | Polyarylamide 30-60% glass fiber | 0.100 | 0.400 |

| PBT | Polybutylene Terephthalate | 0.500 | 2.200 |

| PBT 30% GF | Polybutylene Terephthalate 30% glass fiber | 0.200 | 1.000 |

| PC 20-40% GF | Polycarbonate 20-40% glass fiber | 0.100 | 0.500 |

| PC 20-40% GF FR | Polycarbonate 20-40% glass fiber flame retardant | 0.100 | 0.500 |

| PC high heat | Polycarbonate high heat | 0.700 | 1.000 |

| PC/PBT | Polycarbonate/Polybutylene Terephthalate blend | 0.600 | 1.100 |

| PCTFE | Polymonochlorotrifluoroethylene | 0.500 | 1.500 |

| PE 30% GF | Polyethylene 30% glass fiber | 0.200 | 0.600 |

| PEEK | Polyetheretherketone | 1.200 | 1.500 |

| PEEK 30% CF | Polyetheretherketone 30% carbon fiber | 0.000 | 0.500 |

| PEEK 30% GF | Polyetheretherketone 30% glass fiber | 0.400 | 0.800 |

| PEI | Polyetherimide | 0.700 | 0.800 |

| PEI 30% GF | Polyetherimide 30% glass fiber | 0.200 | 0.400 |

| PEI mineral filled | Polyetherimide mineral filled | 0.500 | 0.700 |

| PEKK– Low cristallinity grade | Polyetherketoneketone– Low cristallinity grade | 0.004 | 0.005 |

| PESU | Polyethersulfone | 0.600 | 0.700 |

| PESU 10-30% GF | Polyethersulfone 10-30% glass fiber | 0.200 | 0.300 |

| PET | Polyethylene Terephtalate | 0.200 | 3.000 |

| PET 30% GF | Polyethylene Terephtalate 30% glass fiber | 0.200 | 1.000 |

| PET 30/35% GF Impact modified | Polyethylene Terephtalate 30/35% glass fiber impact modified | 0.200 | 0.900 |

| PET G | Polyethylene Terephtalate Glycol | 0.200 | 1.000 |

| PE-UHMW | Polyethylene -Ultra High Molecular Weight | 4.000 | 4.000 |

| PFA | Perfluoroalkoxy | 3.000 | 5.000 |

| PHB – Polyhydroxybutyrate | Polyhydroxybutyrate | 1.200 | 1.600 |

| PI | Polyimide | 0.200 | 1.200 |

| PLA-injection molding | Polylactide-injection molding | 0.300 | 0.500 |

| PMMA | Polymethylmethacrylate (Acrylic) | 0.200 | 0.800 |

| PMMA high heat | Polymethylmethacrylate (Acrylic) high heat | 0.200 | 0.800 |

| PMMA Impact modified | Polymethylmethacrylate (Acrylic) impact modified | 0.200 | 0.800 |

| PMP | Polymethylpentene | 1.600 | 2.100 |

| PMP 30% GF | Polymethylpentene 30% glass fiber | 0.300 | 1.200 |

| PMP mineral filled | Polymethylpentene mineral filled | 1.400 | 1.700 |

| Polyamide 66 (Nylon 66)/Carbon Fiber, Long, 30 % Filler by Weight | Polyamide 66 (Nylon 66)/Carbon Fiber, Long, 30 % Filler by Weight | 0.300 | 0.300 |

| Polyamide 66 (Nylon 66)/Carbon Fiber, Long, 40 % Filler by Weight | Polyamide 66 (Nylon 66)/Carbon Fiber, Long, 40 % Filler by Weight | 0.300 | 0.300 |

| Polyamide 66 (Nylon 66)/Glass Fiber, Long, 40 % Filler by Weight | Polyamide 66 (Nylon 66)/Glass Fiber, Long, 40 % Filler by Weight | 0.300 | 0.300 |

| Polyamide 66 (Nylon 66)/Glass Fiber, Long, 40 % Filler by Weight | Polyamide 66 (Nylon 66)/Glass Fiber, Long, 40 % Filler by Weight | 0.300 | 0.300 |

| Polyamide 66 (Nylon 66)/Glass Fiber, Long, 50 % Filler by Weight | Polyamide 66 (Nylon 66)/Glass Fiber, Long, 50 % Filler by Weight | 0.300 | 0.300 |

| Polyamide 66 (Nylon 66)/Glass Fiber, Long, 50 % Filler by Weight | Polyamide 66 (Nylon 66)/Glass Fiber, Long, 50 % Filler by Weight | 0.300 | 0.300 |

| Polyamide 66 (Nylon 66)/Glass Fiber, Long, 60 % Filler by Weight | Polyamide 66 (Nylon 66)/Glass Fiber, Long, 60 % Filler by Weight | 0.300 | 0.300 |

| Polyamide 66 (Nylon 66)/Glass Fiber, Long, 60 % Filler by Weight | Polyamide 66 (Nylon 66)/Glass Fiber, Long, 60 % Filler by Weight | 0.300 | 0.300 |

| Polypropylene Homopolymer (PP Homopolymer)/Glass Fiber, Long, 30 % Filler by Weight | Polypropylene Homopolymer (PP Homopolymer)/Glass Fiber, Long, 30 % Filler by Weight | 0.400 | 0.400 |

| Polypropylene Homopolymer (PP Homopolymer)/Glass Fiber, Long, 40 % Filler by Weight | Polypropylene Homopolymer (PP Homopolymer)/Glass Fiber, Long, 40 % Filler by Weight | 0.300 | 0.300 |

| Polypropylene Homopolymer (PP Homopolymer)/Glass Fiber, Long, 40 % Filler by Weight | Polypropylene Homopolymer (PP Homopolymer)/Glass Fiber, Long, 40 % Filler by Weight | 0.300 | 0.300 |

| Polypropylene Homopolymer (PP Homopolymer)/Glass Fiber, Long, 50 % Filler by Weight | Polypropylene Homopolymer (PP Homopolymer)/Glass Fiber, Long, 50 % Filler by Weight | 0.300 | 0.300 |

| Polypropylene Homopolymer (PP Homopolymer)/Glass Fiber, Long, 50 % Filler by Weight | Polypropylene Homopolymer (PP Homopolymer)/Glass Fiber, Long, 50 % Filler by Weight | 0.300 | 0.300 |

| POM | Polyoxymethylene (acetal) | 1.800 | 2.500 |

| POM impact modified | Polyoxymethylene (acetal) impact modified | 1.000 | 2.500 |

| POM low friction | Polyoxymethylene (acetal) low friction | 1.800 | 3.000 |

| POM mineral filled | Polyoxymethylene (acetal) mineral filled | 1.500 | 2.000 |

| PP 10-20% GF | Polypropylene 10-20% glass fiber | 0.300 | 1.000 |

| PP 10-40% mineral filled | Polypropylene 10-40% mineral filled | 0.600 | 1.400 |

| PP 10-40% TALC | Polypropylene 10-40% talc | 0.900 | 1.400 |

| PP 30-40% GF | Polypropylene 30-40% glass fiber | 0.100 | 1.000 |

| PP copo | Polypropylene copolymer | 2.000 | 3.000 |

| PP homo | Polypropylene homopolymer | 1.000 | 3.000 |

| PP impact modified | Polypropylene impact modified | 2.000 | 3.000 |

| PPA | Polyphthalamide | 1.500 | 2.200 |

| PPA – 30% mineral | Polyphthalamide– 30% mineral | 1.000 | 1.200 |

| PPA – 33% glass fiber | Polyphthalamide – 33% glass fiber | 0.500 | 0.700 |

| PPA – 33% glass fiber – high flow | Polyphthalamide– 33% glass fiber – high flow | 0.740 | 0.760 |

| PPA – 45% glass fiber | Polyphthalamide– 45% glass fiber | 0.100 | 0.300 |

| PPE | Polyphenylene Ether | 0.500 | 0.800 |

| PPE 30% GF | Polyphenylene Ether 30% glass fiber | 0.100 | 0.400 |

| PPE FR | Polyphenylene Ether flame retardant | 0.600 | 1.000 |

| PPE impact modified | Polyphenylene Ether impact modified | 0.600 | 1.000 |

| PPE mineral filled | Polyphenylene Ether mineral filled | 0.300 | 0.700 |

| PPS | Polyphenylene Sulfide | 0.600 | 1.400 |

| PPS 20-30% GF | Polyphenylene Sulfide 20-30% glass fiber | 0.200 | 0.500 |

| PPS 40% GF | Polyphenylene Sulfide 40% glass fiber | 0.200 | 0.500 |

| PPS conductive | Polyphenylene Sulfide conductive | 0.300 | 1.000 |

| PPS GF & mineral | Polyphenylene Sulfide glass fiber & mineral | 0.300 | 0.700 |

| PS 30 % GF | Polystyrene 30% glass fiber | 0.200 | 0.200 |

| PS crystal | Polystyrene crystal | 0.100 | 0.700 |

| PS high heat | Polystyrene high heat | 0.200 | 0.700 |

| PSU | Polysulfone | 0.700 | 0.700 |

| PSU 30% GF | Polysulfone 30% glass fiber | 0.100 | 0.600 |

| PSU mineral filled | Polysulfone mineral filled | 0.400 | 0.500 |

| PTFE | Polytetrafluoroethylene | 3.000 | 6.000 |

| PTFE 25% GF | Polytetrafluoroethylene 25% glass fiber | 1.800 | 2.000 |

| PVC 20% GF | Polyvinyl Chloride 20% glass fiber | 0.100 | 0.200 |

| PVC plasticized | Polyvinyl Chloride plasticized | 0.200 | 4.000 |

| PVC plasticized filled | Polyvinyl Chloride plasticized filled | 0.800 | 5.000 |

| PVC rigid | Polyvinyl Chloride rigid | 0.100 | 0.600 |

| PVDC | Polyvinylidene Chloride | 0.500 | 2.500 |

| PVDF | Polyvinylidene Fluoride | 2.000 | 4.000 |

| SAN | Styrene Acrylonitrile | 0.300 | 0.700 |

| SAN 20% GF | Styrene Acrylonitrile 20% glass fiber | 0.100 | 0.300 |

| SMA | Styrene Maleic Anhydride | 0.400 | 0.800 |

| SMA 20% GF | Styrene Maleic Anhydride 20% glass fiber | 0.200 | 0.300 |

| SMA FR V0 | Styrene Maleic Anhydride flame retardant V0 | 0.500 | 0.500 |

| TPS-Injection General Purpose | Thermoplastic Starch GP | 0.600 | 1.500 |

| TPS-Injection Water Resistant | Thermoplastic Starch WR | 0.600 | 0.900 |

| XLPE – Crosslinked Polyethylene | XLPE – Crosslinked Polyethylene | 0.700 | 5.000 |