Atomstack P9 Ebay

Atomstack P9 Amazon

220 X axis x 250Y axis

Y axis is perpendicular to control box.

Atomstack

Has filtering lens for reflective surfaces.

Enclosure

Exhaust

Materials

wood, bamboo, cardboard, plastic, leather, PCB board, alumina, non-reflective electroplated and lacquered metal, 304 mirror stainless steel, glass, ceramic, cotton cloth, slate

P9 air assist.

Magnets

Speed Square

On stainless steel, there is no need for pretreatment.

You can get visible marks on the surface,

but if you want to get darker marks,

it is better to use a special compound.

Usually, it is called metal marking spray.

A thin and even coat of spray is applied to the metal.

After that, the laser beams react with this compound and leave a darker mark that is more visible.

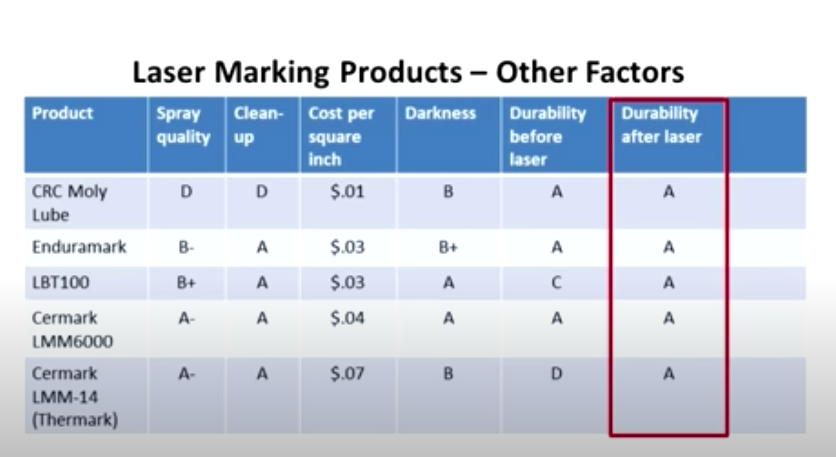

Molybdenum Disulfide

CRC Dry 084 for EtMoly 3ching Stainless Steel Ebay

CRC3084 Amazon

Tips

Borax

Denatured Alcohol

Gray Primer (spray on metal plate for acrylic etching)

Alcohol Mix with Tempera Paint

Fine Mist Spray Bottle

Air Brush

Brilliance Spray BL10M1... Not Recomended by Mfg. But seems to work.

Cermark $$$